HardwareProjects - Mill Board Electronics

February 2015

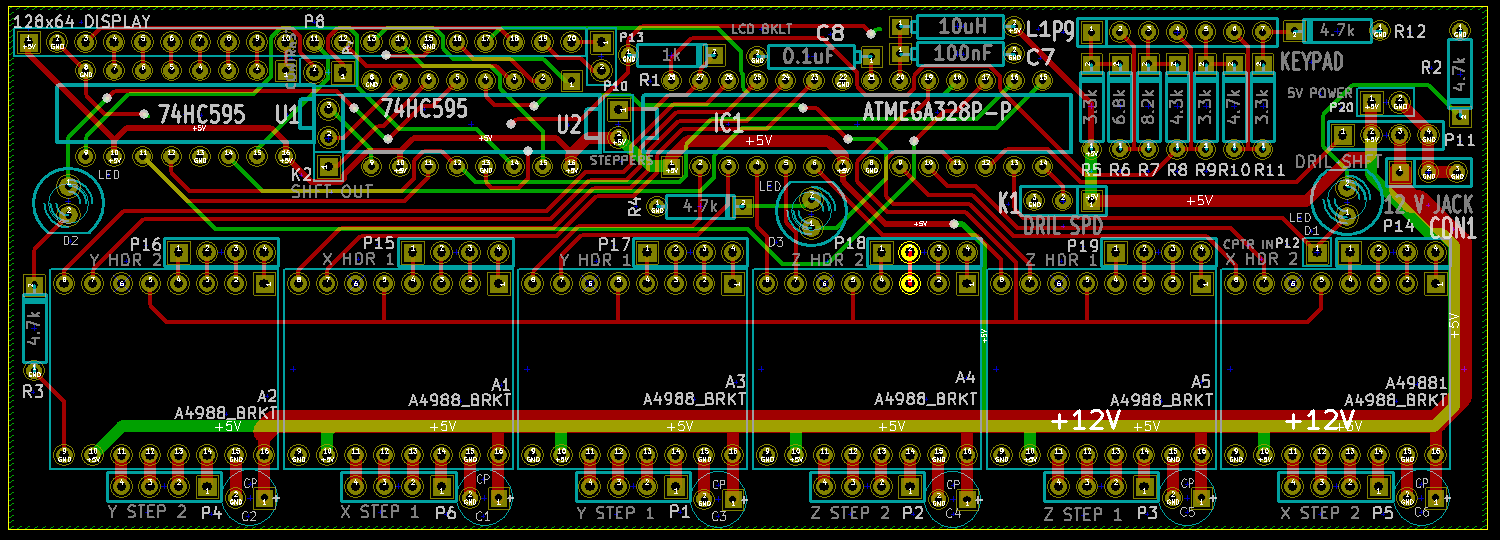

Conceptual Design

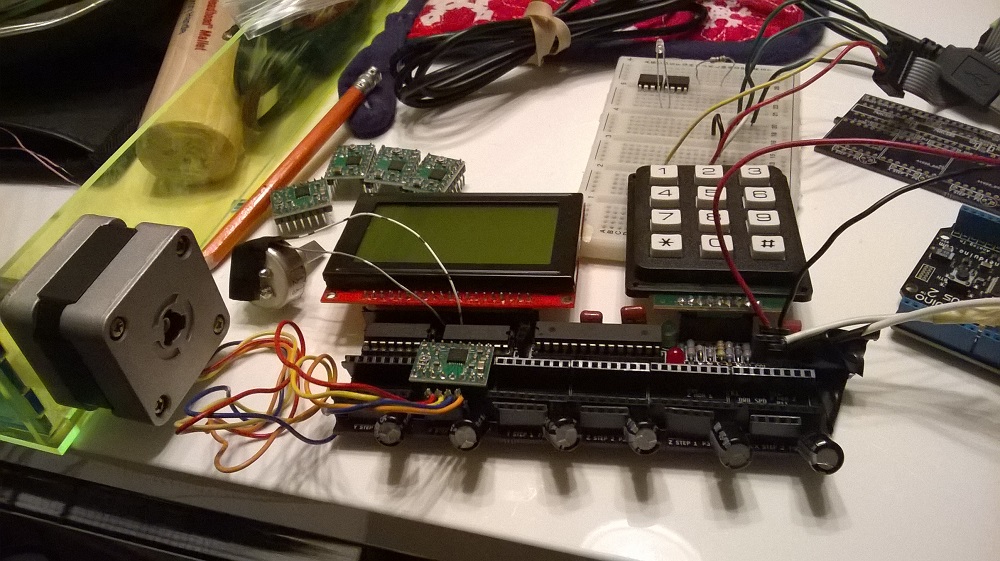

This project was initially to create a low-cost, custom electronics board capable of driving six stepper motors.

Because my mill design was unusual in requiring six stepper motors, currently-available boards such as the RAMPS board

and other electronics were not be capable of driving my mill.

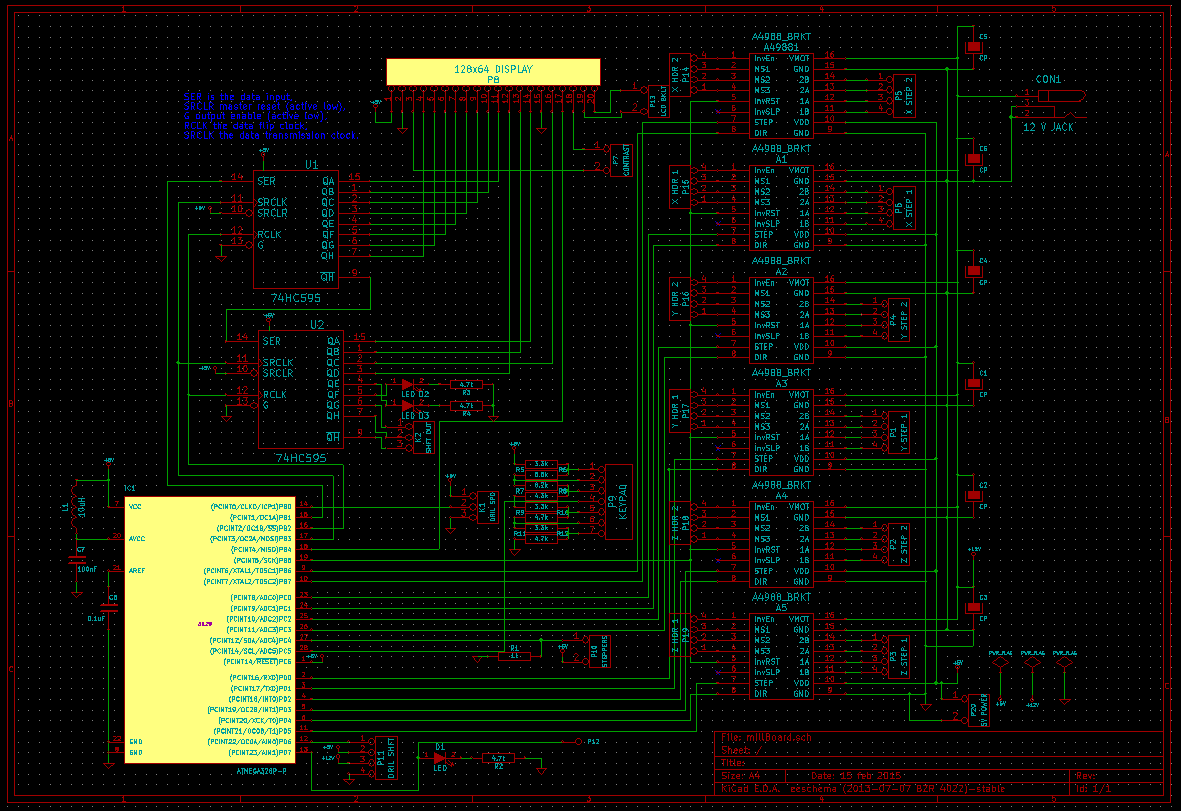

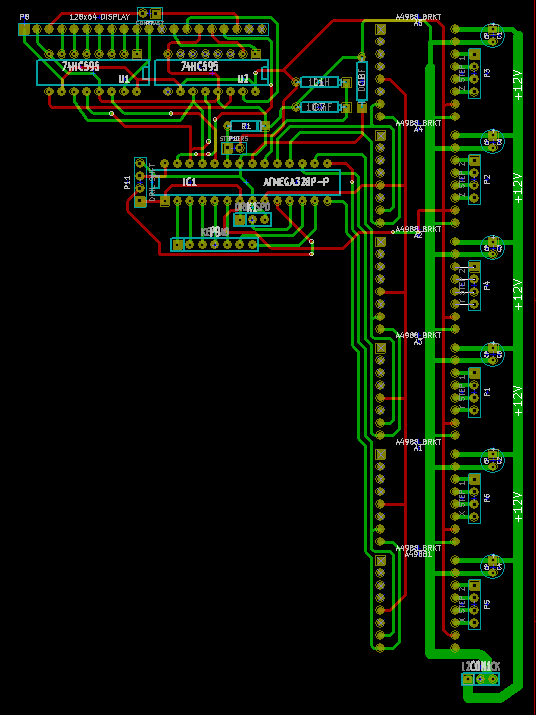

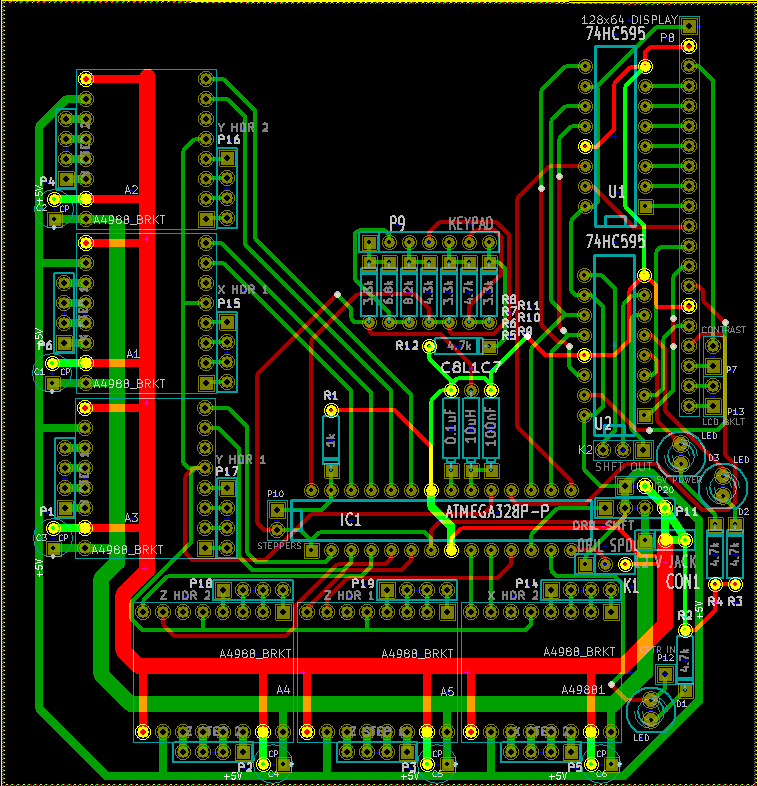

To construct the electronics board, I prototyped a PCB with KiCad and send the design out for

manufacturing to OSH Park. Because OSH Park charges for the amount of surface area used, I attempted to collapse

a 12-pin keypad, a 128x64 LCD display, six stepper motor drives and an ATmega328P-PU microcontroller all on the single board.

To support all of these devices, I also used a few serial-to-parallel chips to increase the total number of I/O pins available.

Pins required:

- Six stepper motor drivers: 1 (reset) + 6*2 (direction + step) = 13 (output)

- Drill Bit PWM: 1 (speed selection) = 1 (output)

- Drill Bit PWM speed indicator: 1 (actual drill bit speed) = 1 (input)

- 12-button keypad: 1 (current button press value) = 1 (analog input)

- General-purpose potentiometer: 1 (current dial value) = 1 (analog input)

- Computer input line: 1 (data input) = 1 (input)

- 128x64 display: 8 (data lines) + 2 (chip selection) + 3 (reset / clock / command (or) data) = 13 (output)

- Status LEDs: 2

- Total: 33

Finally, to complete the design I ensured that:

- Each stepper motor driver has two headers -- one to swap out the motor, the other to swap out the driver.

- Each stepper motor driver has it's own transient protection capacitor on the 12 V line.

- The ATmega has additional passive components to reduce the noise on the analog reference 5 V line.

- The keypad uses a resistor network to uniquely idenfity each key (which creates a short on two of its pins), to significantly reduce the pin count to 1.

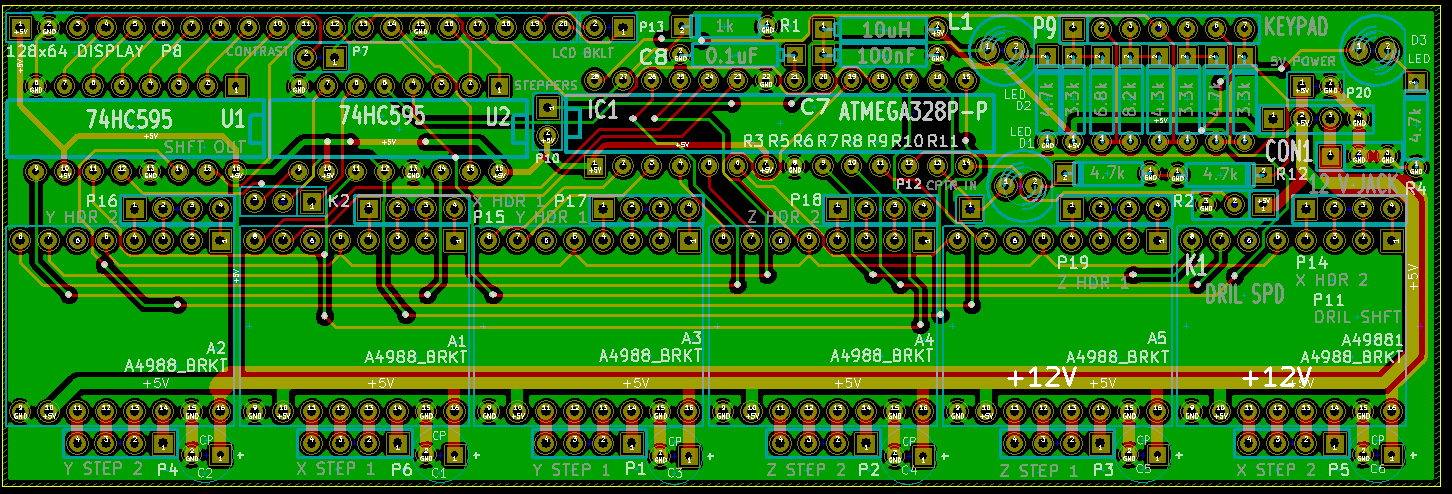

PCB Design

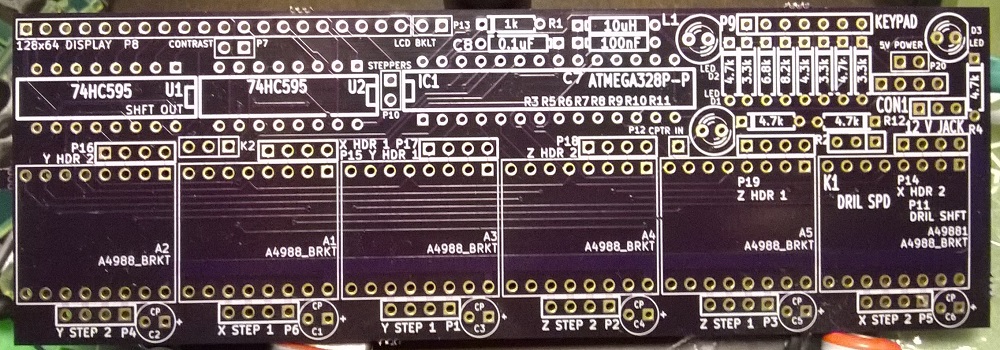

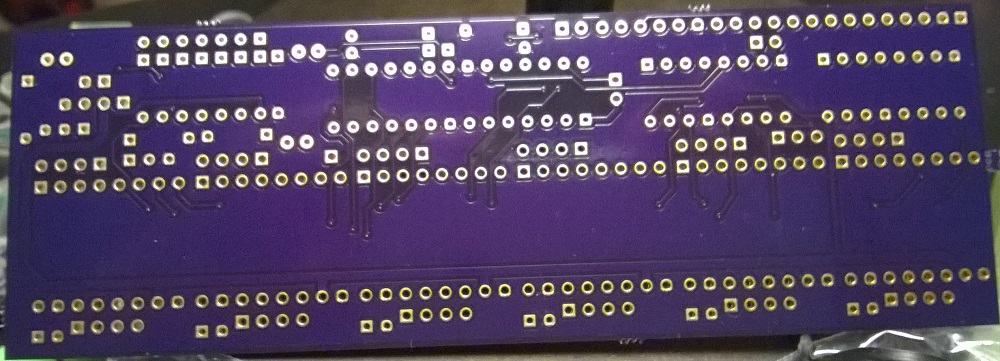

Final Results

After about a month of lead time, I received the order I had submitted.

Testing

I went through two main phases testing these boards -- mechanical and electrical -- to verify the results.

Mechanical Design Errors

- Major: The stepper-motor sockets were all 1-pin spaced too far apart (oops). Pins fit when bent.

- Minor: The capacitor pads were too small, so all the capacitors were placed sideways.

- Minor: The LCD covers the backlight pads -- which was OK, because I wasn't planning on using the backlight.

- Minor: I used the wrong sized-pads for the keypad, so it only accepts smaller pin sizes -- such as the pin sizes the keypad has.

Electrical Design Errors

None found so far!